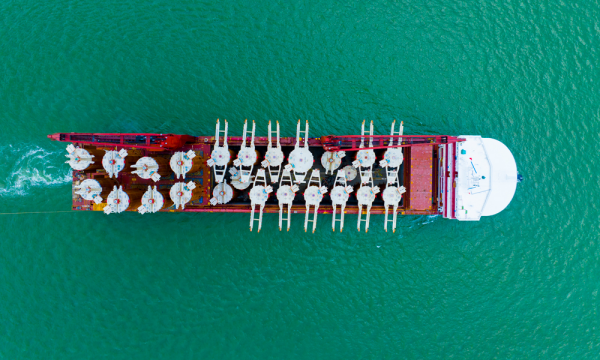

China Offshore Oil Engineering Co., Ltd. (COOEC) has successfully delivered 24 sets of 2,000-meter-class ultra-deepwater suction anchors for shipping from Zhuhai, Guangdong Province, to Brazil.

Twenty-four sets of 2,000-meter-class ultra-deepwater suction anchors were recently loaded for shipping from Zhuhai, Guangdong Province, to Brazil. [Photo/sasac.gov.cn]

These anchors are destined for deployment in the second phase of Brazil’s Mero oilfield, a significant project in one of the world's largest pre-salt ultra-deepwater fields. This achievement not only signifies the growing recognition of China's advanced offshore oil and gas equipment manufacturing capabilities but also highlights the country's presence in mainstream global markets for deep-sea operations.

Each suction anchor for the project reaches a height of up to 21 meters and a diameter of 8 meters. [Photo/sasac.gov.cn]

The anchors delivered for the Mero project are designed for installation at depths beyond 2,000 meters — making it the deepest such project ever undertaken by a Chinese contractor. All 24 units were designed, built, and loaded at COOEC’s Zhuhai Deepwater Equipment Manufacturing Base, with a total structural weight of approximately 2,674 tons.

All 24 units were designed, built, and loaded at COOEC’s Zhuhai Deepwater Equipment Manufacturing Base, with a total structural weight of approximately 2,674 tons. [Photo/sasac.gov.cn]

Each suction anchor for the project reaches a height of up to 21 meters and a diameter of 8 meters, with a wall thickness of only 25 millimeters, posing significant challenges in precision engineering and construction.

To meet these demands, the project team pioneered several key innovations in China, including a horizontal extension and vertical assembly commissioning process for ultra-deepwater suction anchors. By widely applying advanced technologies, they overcame issues in dimensional accuracy of large-diameter and deformation control of thin-walled structures. As a result, the anchors achieved a quality pass rate of over 99.9 percent, with dimensional deviations controlled within 1 millimeter per meter, reaching an advanced level in the industry.

In recent years, COOEC has significantly enhanced its expertise in core technologies for deepwater oil and gas equipment. The company has delivered several landmark projects, including China’s first 100,000-ton-class semi-submersible oil production and storage platform, as well as Brazil’s 350,000-ton floating oil-gas production, storage and offloading units. These achievements have helped elevate the reputation of “Made in China” in the global deepwater oil and gas equipment market, contributing to high-level international cooperation in marine energy and supporting energy development in Belt and Road partner countries.

(Executive editor: Yuan Ting)