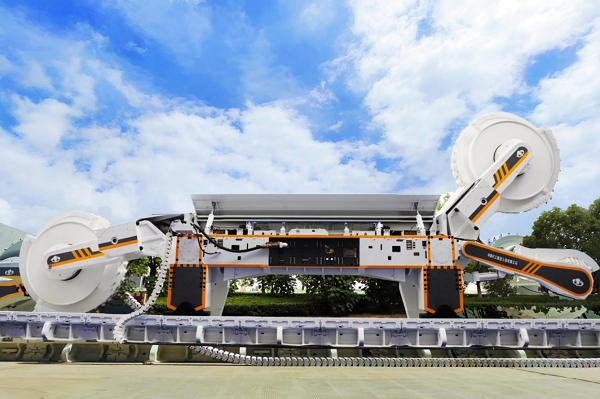

The MG1250/3430-WD intelligent high-end shearer with the world's largest power and super large mining height was released at the research institute of China Coal Technology Engineering Group in Shanghai, on Aug 22.

The company launched the intelligent shearers with ultra-large mining height and ultra-high-power in 2019. This is the second time that the company has made a breakthrough in installed power and mining height of coal mining machines, pushing the development of global mining machinery to a new height.

The MG1250/3430-WD intelligent high-end shearer with the world's largest power and super large mining height is released. [Photo/sasac.gov.cn]

This series of shearer integrates intelligent perception, control, diagnosis and communication, effectively catering to the needs of intelligent and labor-saving operation of fully mechanized coal mining faces.

It is specifically designed for the development of coal seams with thickness ranging from 7 to 10 meters, and boasts a cutting power of 1,250 kilowatts, a traction power of 250 kilowatts, an installed power of 3,430 kilowatts, and a maximum mining height of 10 meters. It provides technical support for safe, efficient, and intelligent mining at coal faces with a super large mining height.

"The MG1250/3430-WD series shearer has presented a number of advanced technological achievements of the Shanghai Research Institute of China Coal Technology Engineering Group," said the technical head of the project.

The research team has achieved technological breakthroughs in the low-center-of-gravity machine body structure of large coal shearers, innovatively designed the rocker arm two-way active lubrication and triple cooling system, as well as invented the machine body connection status intelligent monitoring system and the embedded intelligent grease injection system. The research team has also developed remote control technology with high reliability, low latency, and low bandwidth requirements based on redundant communication networks. In addition, the team has conducted research and development on an intelligent planning and cutting control system for coal shearers based on multi-source data fusion, and the remote pre-sensing operation and maintenance system for online monitoring and remote operation and maintenance of the machine.

This series shearer effectively resolves the problem of low resource recovery rate that traditional mining methods present and can meet the needs of high-efficiency mining. Only two such shearers are able to meet the annual coal demand of Shanghai for power generation.

"The successful development and application of the MG1250/3430-WD shearer will further promote the green, safe, energy-saving and efficient mining of coal in China, which is of great significance in ensuring independent and controllable national energy development," the project technical head said.

(Executive editor: Xie Yunxiao)