The first steel box girder of the Huangmaohai Bridge, the world's largest cable-stayed bridge with three towers, is recently hoisted into place, marking the beginning of the construction of the upper structure of the bridge. [Photo/sasac.gov.cn]

The first steel box girder of the Huangmaohai Bridge, the world's largest cable-stayed bridge with three towers, constructed by China Railway Hi-Tech Industry Co., Ltd., a subsidiary of China Railway Group Limited, was recently hoisted into place, marking the beginning of the construction of the upper structure of the bridge.

The first steel box girder of the Huangmaohai Bridge, the world's largest cable-stayed bridge with three towers, is recently hoisted into place, marking the beginning of the construction of the upper structure of the bridge. [Photo/sasac.gov.cn]

The Huangmaohai Bridge is a key control project and has a length of 2,200 meters. The main girder is composed of two split steel box girders and a horizontal connecting box. There are 16 types of girder segments and 149 girder segments, with a total steel structure weight of approximately 60,000 tons. The hoisted steel box girder is 22.5 meters long, 19.7 meters wide, 4 meters tall, and weighs about 355 tons. It is manufactured by Zhongtie Baoqiao Group Company Limited, a subsidiary of China Railway Hi-Tech Industry Co., Ltd.

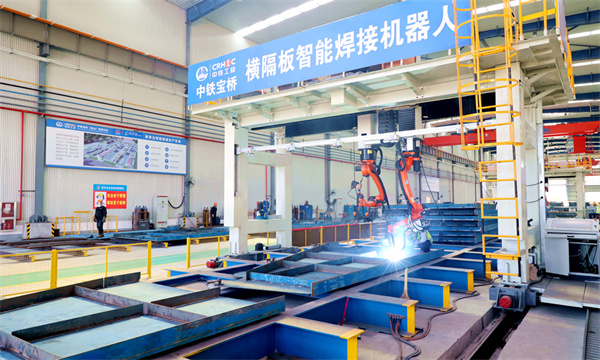

Given the complexity of the structural form of the Huangmaohai Bridge, during the steel structure manufacturing process, Zhongtie Baoqiao Group Company Limited has built an intelligent steel cutting-stock production line, an intelligent steel unit welding production line, an intelligent segment assembly line, an intelligent steel box girder coating production line, and an intelligent steel guardrail production line, as well as an information-based production command system for steel box girder intelligent manufacturing.

The first steel box girder of the Huangmaohai Bridge, the world's largest cable-stayed bridge with three towers, is recently hoisted into place, marking the beginning of the construction of the upper structure of the bridge. [Photo/sasac.gov.cn]

Among them, on China's first intelligent steel guardrail production line, the utilization rate of intelligent equipment for manufacturing has reached 100 percent, resulting in a production efficiency improvement of more than 40 percent compared with traditional production methods.

In response to the frequent occurrence of typhoons in the construction sea area, the project team has also developed the technology and complete equipment for erecting split steel box girders in typhoon-prone areas, which effectively ensures construction safety and project quality during typhoon seasons.

The first steel box girder of the Huangmaohai Bridge, the world's largest cable-stayed bridge with three towers, is recently hoisted into place, marking the beginning of the construction of the upper structure of the bridge. [Photo/sasac.gov.cn]

The Huangmaohai Bridge is the first cross-sea channel to be built since the release of the Outline Development Plan for the Guangdong-Hong Kong-Macao Greater Bay Area. As an extension project westward of the Hong Kong-Zhuhai-Macao Bridge, it starts from Gaolan Port in Zhuhai City and ends at Taishan City, Guangdong Province. It has a total length of 31 kilometers and is expected to be completed and open to traffic by the end of 2024. Upon its completion, a cross-sea and cross-river passage network in the Greater Bay Area will be formed together with projects such as the Hong Kong-Zhuhai-Macao Bridge, the Shenzhen-Zhongshan Channel, the Nansha Bridge, and the Humen Bridge, which will accelerate the formation of a world-class transportation hub and help build a new regional development pattern in Guangdong.

(Executive editor: Xie Yunxiao)