On March 28, the Yongtai pumped storage power station in East China's Fujian Province entered full operation, with all its turbines built by Dongfang Electric Corporation (DEC) leveraging virtual assembly technology to increase accuracy and efficiency.

The turbines were produced at a digital factory for manufacturing large-scale clean energy equipment that features heavy machinery processing and control, digital assembly, and robot welding.

The digital assembly technology utilizes intelligent 3D measurements to obtain accurate product models and perform assembly simulations, enabling efficient and comprehensive analysis and optimization of water turbine assembly results.

This factory is equipped with a cluster of robot-integrated intelligent welding systems that utilizes 5G, automation control and the internet of things (IoT) to achieve cluster control and data-driven welding, which has significantly improved the work environment for welding workers and has resulted in an enhanced quality of welding.

"So far, we have built 13 digital factories. We plan to work on digital transformation covering all our key manufacturing factories by 2025," said Liu Boxing, a digital expert at DEC.

A view of DEC’s industry-leading unmanned production line for turbine blades [Photo provided by DEC]

Aided by such smart technologies as 5G, industrial internet, digital twins and machine vision, DEC's industry-leading unmanned production line for turbine blades achieves 24/7 continuous processing without human intervention, with an energy utilization rate increase of 47 percent, according to Liu.

DEC's unmanned stator punching workshop features automated, data-driven operation, production and management, with an energy utilization rate increase of 56.6 percent, and a labor intensity reduction of 90 percent.

DEC has also built smart hydropower systems that enable the real-time assessment and fault diagnosis of unit operation status, with 240 diagnostic models having already been established.

In addition, it has adopted intelligent solutions to wind farm operations to increase wind power generation efficiency as well as reduce wind turbine failures and electricity consumption.

So far, DEC has made breakthroughs in the development of clean energy equipment, such as China's first homegrown F-class 50MW heavy-duty gas turbine.

Supported by technological advancement, DEC has also taken the lead in providing reliable clean energy solutions to energy storage and hydrogen energy development.

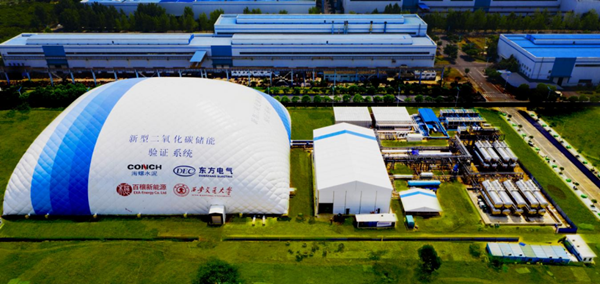

A view of the CO2 plus flywheel energy storage demonstration project built by DEC [Photo provided by DEC]

It has built the world's first pilot project for a carbon dioxide plus flywheel energy storage power plant - a green, powerful and efficient project marking a significant leap forward in the engineering application of this new energy storage technology in China.

In a bid to support China's action plan to advance the hydrogen energy industry, DEC has established a complete industrial chain for hydrogen production, storage, transportation and utilization, providing comprehensive green hydrogen energy solutions to facilitate green energy transition and achieving China's carbon peak and neutrality goals.

(Executive editor: Wang Ruoting)