A trial operation was successfully completed on the Jakarta-Bandung High-Speed Railway in Indonesia on Nov 16.

A flagship project under the framework of the Belt and Road Initiative, it is the first high-speed railway in Indonesia and Southeast Asia.

Connecting Indonesia's capital Jakarta and Bandung, a city well-known for tourism, the 142.3-kilometer railway has a maximum operation speed of 350 kilometers per hour. Its construction started in June 2018. It will shorten travel time between the two cities from over three hours to 40 minutes.

As the first high-speed railway exported by China to a foreign country, the railway was built to Chinese standards with Chinese technologies by Chinese equipment.

All of the railway's systems related to the roadbed, rail, bridges, tunnels, overhead lines, communication signals, train operation and customer service adopted Chinese standards.

Its survey and design, engineering and construction, equipment manufacturing, operation and management and development were done in accordance with Chinese solutions.

In addition, equipment for engineering and facilities like overhead lines, steel rails, and multiple carriages were built by Chinese enterprises.

Chinese central state-owned enterprises (SOEs) played an indispensable role in the successful trial operation of the high-speed railway.

China-developed high-speed train runs overseas

Both the high-speed trains and the comprehensive test train used in the recent trial operation were designed and manufactured by CRRC Qingdao Sifang Co., Ltd., a subsidiary of CRRC Corporation Limited (CRRC).

One of the high-speed trains specially-manufactured for the Jakarta-Bandung High-Speed Railway in Indonesia [Photo/sasac.gov.cn]

A view of the comprehensive test train used in the trial operation on Nov 16 [Photo/sasac.gov.cn]

Based on the mature advanced technologies of China's Fuxing high-speed trains, the trains built for the Jakarta-Bandung High-Speed Railway are adjusted to adapt to the local operation environment and route conditions.

The trains are painted in silver and red, symbolizing advanced technology and prosperity. The image on the front of the trains and carriage connection part is painted in the shape of Komodo dragon, a national treasure in Indonesia, which reflects the harmonious development of man and the nature.

The test train is painted in yellow and is equipped with testing functions targeting the railway, the overhead lines and the communication signal system.

To date, all 12 trains including 11 operational trains and one test train were completed in Qingdao, East China's Shandong Province, and one train and the test train have been shipped to Jakarta Port. Other trains are scheduled for delivery to Indonesia by early 2023.

China-built railway, bridges, tunnels and stations ensure safe operation of Jakarta-Bandung High-Speed Railway

Power Construction Corporation of China (POWERCHINA) is responsible for about 85 kilometers of under-track works and track-laying of the entire line.

POWERCHINA starts track-laying of the Jakarta-Bandung High-Speed Railway. [Photo/sasac.gov.cn]

The entire Jakarta-Bandung High-Speed Railway features three girder fabrication yards responsible for all box girders prefabrication and erection. The Nos 1 and 2 yards were built by POWERCHINA and No. 4 was built by China Railway Group Limited (CRCC).

The No. 1 girder fabrication yard is the largest overseas girder building yard for high-speed trains and the No. 2 yard is the first of the three to be approved for operation. On Oct 16, 2022, the two yards completed girder erection work of the entire line.

Workers at the No. 1 girder fabrication yard pose after completion of the girder erection work. [Photo/sasac.gov.cn]

Fabrication and erection of 1,066 box girders were shouldered by the No. 4 yard, which is the largest of the three yards with the highest standardization. It also produced the most girders for the railway. It's worth noting that the first overseas girder for a China-developed high-speed railway was made at the No. 4 yard, which is the first overseas smart girder yard for export of Chinese high-speed railway components.

A view of the No. 4 girder yard built by China Railway No. 4 Engineering Group Co., Ltd. [Photo/sasac.gov.cn]

The railway includes 13 tunnels and POWERCHINA is responsible for construction of five of them.

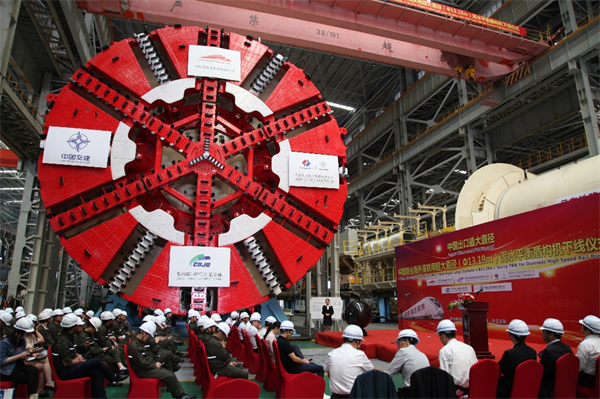

The No. 1 tunnel is 1,885 meters and the deepest part runs 26 meters under the earth. The tunnel boring machine (TBM) developed by China Communications Construction Company Limited (CCCC), has a 13.19-meter diameter cutter as well as the largest diameter slurry shield in Southeast Asia.

A view of the TBM developed by CCCC that was used in construction of the No. 1 tunnel of the Jakarta-Bandung High-Speed Railway [Photo/sasac.gov.cn]

The longest tunnel of the railway is the No. 6 tunnel which is 4,478 meters. CRCC adopted various kinds of engineering methods to guarantee on-schedule and safe construction. The tunnel was dug through on Feb 18, 2022. the railway section in and near the tunnel was laid with ballastless track that was developed by China. It has a simple structure and stable performance and is used in construction of many high-speed railways in China.

A bird's-eye view of the No. 6 tunnel of the Jakarta-Bandung High-Speed Railway [Photo/sasac.gov.cn]

The Tegallur Station built by CRCC is the terminal station of the high-speed railway and was the departure station for the recent trial operation.

Located in Tegallur Town, Bandung, the station covers an area of 15,000 square meters and has waiting room for 1,500 passengers. The peak hourly dispatched passengers of the station can reach 3,200. Departing from the station, passengers can reach many scenic spots like the Museum of the Asian-African Conference and the Bandung Zoo.

Jakarta-Bandung High-Speed Railway is witness to China-Indonesia friendship

Travel time between Jakarta and Bandung will be shorten to 40 minutes once the railway is operational. It is expected to help boost economic and social development of Indonesia, deepen China-Indonesia cooperation and promote high-quality Belt and Road co-construction.

Central SOEs also fulfilled their social responsibilities during construction and drove social, livelihood and economic development in affected areas.

Workers at the Jakarta-Bandung High-Speed Railway project of the China Railway No. 4 Engineering Group Co., Ltd. help local villagers build roads. [Photo/sasac.gov.cn]

CRCC cultivates local technicians during the construction. [Photo/sasac.gov.cn]

Workers of CRCC at the railway project visit a local orphanage. [Photo/sasac.gov.cn]

A landmark project of the Belt and Road Initiative and a practical cooperation result of China and Indonesia, the Jakarta-Bandung High-Speed Railway not only shortens travel time between the cities but also brings people in the countries involved in the Initiative closer.

Timeline of construction of the Jakarta-Bandung High-Speed Railway

- Jan 21, 2016: The Jakarta-Bandung High-Speed Railway broke ground

- June 2018: Construction of the railway fully underway

- Sept 24, 2019: First continuous beam was completed

- March 12, 2020: No. 5 tunnel was dug through

- April 26, 2020: No. 3 tunnel was dug through

- May 10, 2020: First multi-span continuous beam was completed

- Sept 1, 2020: First box girder at the No. 2 girder yard was erected

- April 30, 2021: Main structure of the first station was capped

- April 6 2022: The key part of No. 2 tunnel linking inclined tunnel shaft and exit was connected with No. 4 tunnel

- June 21, 2022: All 13 tunnels were dug through

- Oct 16, 2022: Box girder erection and track-laying of the entire railway were completed

- Nov 5, 2022: Overhead lines of the trial section started operation

- Nov 9, 2022: The train firstly operated on the railway for hot sliding test

- Nov 16, 2022: First trial operation of the railway was successfully completed

- June 2023: The Jakarta-Bandung High-Speed Railway is scheduled to start operation

(Executive editor: Li Zhiyong)