China's First Full Automatic Production Line for Digital Simulation Double-Block Ballastless Track put into Operation

China's first full automatic production line for digital simulation double-block ballastless track recently went into operation in Hechi, Guangxi Zhuang Autonomous Region, a milestone of smart manufacturing in China's high-speed railway sleeper industry.

Designed and built by China Railway 14th Bureau Group Co., Ltd., a subsidiary of China Railway Construction Corporation Limited, the production line has four systems with which 16 smart stations along the line can be controlled individually or as a whole, China's first such arrangement of its kind.

Equipped with more than 100 internationally-leading patented technologies, the smart production line is capable of fully-automatic operation with high efficiency and precision.

The sleepers produced by the line will be used in the Guiyang-Nanning High-speed Railway between Guizhou Province and Guangxi which has a designed speed of 350 kilometers per hour.

Such sleepers are expected to be a key to stable and high-speed operation of trains on the railway.

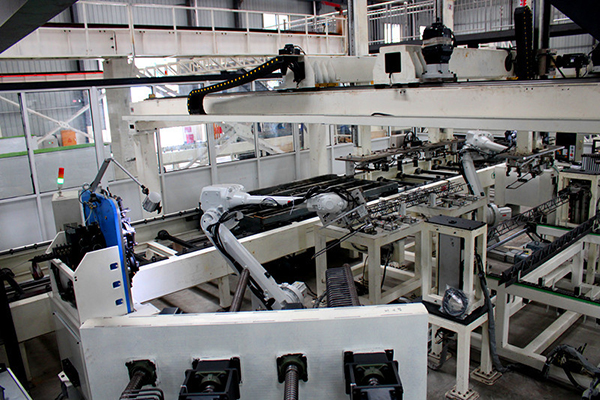

A view of the workshop housing China's first full automatic production line for digital simulation double-block ballastless track [Photo/sasac.gov.cn]

A close view of how a mechanical arm installs a truss bar automatically [Photo/sasac.gov.cn]

(Executive editor: Wang Ruoting)