Construction of first RPV at Phase II of Fangchenggang Nuclear Power Plant ends

Manufacturing of the first reactor pressure vessel (RPV) at the Phase II of Fangchenggang Nuclear Power Plant was completed at the Dalian Nuclear Power and Petro-chemical Business Group of China First Heavy Industries (CFHI) on Nov 29.

The completion lays a solid foundation for the progress of the Phase II project of Fangchenggang Nuclear Power Plant.

The Fangchenggang Phase II power plant is a demonstration project using Hualong One technology -- a domestically developed third-generation reactor design -- and also a reference power station for the Bradwell B Project (BRB) in the UK.

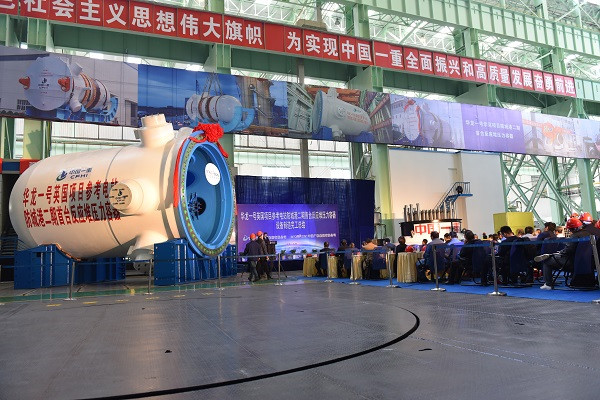

Manufacturing of the first reactor pressure vessel (RPV) at the Phase II of Fangchenggang Nuclear Power Plant is completed on Nov 29. [Photo/sasac.gov.cn]

The project started construction on Dec 24, 2015, and completed dome hoisting of Unit 3 on May 23, 2018.

On Oct 21, 2015, China General Nuclear Power Corporation (CGN) and Electricite De France (EDF) signed a suite of cooperation agreements relating to the UK's new nuclear power plant projects, including BRB. The project will be built with Chinese Hualong One technology.

Hualong One is China's self-developed reactor design. Its safety indicators and technical performance have reached the international advanced level. It fully utilizes China's mature nuclear power equipment manufacturing system, with an equipment localization rate of 90 percent.

It has become one of the national business cards for China on the world stage.

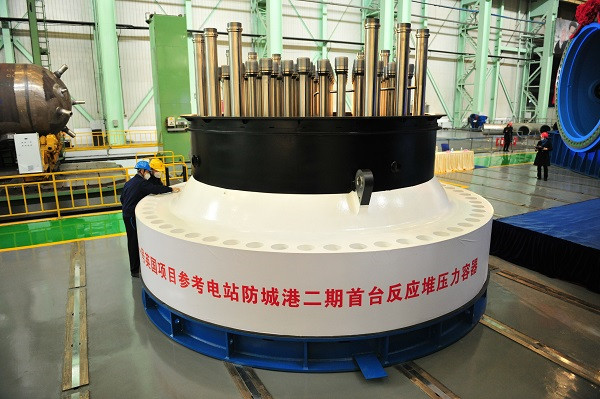

The first RPV at the Phase II of Fangchenggang Nuclear Power Plant [Photo/sasac.gov.cn]

In the manufacturing of the RPV, Dalian Nuclear Power and Petrochemical Business Group undertook the main task. It overcame technical difficulties such as machining the M170 large-diameter bolt pitch, welding large-size and thick-wall radial support keys, nickel-based material safety end welding, and CRDM sealing and welding deformation control, and passed quality inspection. At the same time, it set a record for mass production of five sets of nuclear reactor pressure vessels.

The completion of the RPV indicates that CFHI's ability to manufacture one-million-kilowatt RPVs has been further enhanced, as has its ability to manufacture other autonomous and mass-produced products.

It also indicates that CFHI has made positive contributions to the revitalization of the old industrial bases in northeast China, and taken a new step forward in the process of promoting the construction of the Belt and Road and the development of localized nuclear power in China.

(Executive editor: Li Shuling)